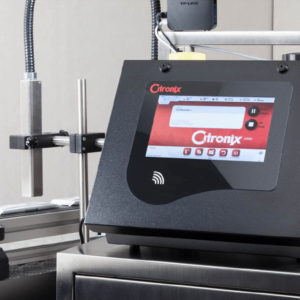

Continuous Inkjet Printer

Continuous Inkjet is also often abbreviated as CIJ and is the English name for a printing technology that uses a continuous inkjet. Continuous Inkjet does not require direct contact with the surface to be marked. The products are fed past the print head. In this process, small drops of ink are shot onto the product surface, resulting in the desired printed image.

What are the advantages of Continuous Inkjet?

Continuous inkjet is particularly suitable for marking large quantities due to the low variable printing costs.

- Fast printing speed up to 588 m/min

- Large distance of up to 5.0 cm from printhead to product

What do continuous inkjet printers print on?

- Printing on round, uneven and smooth surfaces thanks to non-contact printing technology

- Industry-specific solutions with adhesion to almost all surfaces thanks to the large ink portfolio

- High print quality of logos, barcodes, 2D codes and texts

How does continuous inkjet printing work?

Continuous Inkjet printing technology, with the help of outstanding technological developments, produces very precisely placed type, making it suitable for logo and barcode printing. The process is made possible by an inkjet.

This jet, which is composed of individual ink drops, moves continuously toward the object to be printed. At the same time, the focus of the beam is not interrupted at any time. As a result, the ink globules move towards the object even during a pause in printing, but in this case they remain motionless. As soon as the printing process is initiated, the particles become electrically charged.

A developing high-voltage field gives the color particles their direction. In this way, they immediately and exactly reach the place set on the device. Interestingly, that process produces a precise print result through individual charging processes during the printing process.